Most Recent Program Information

June 2019 Program

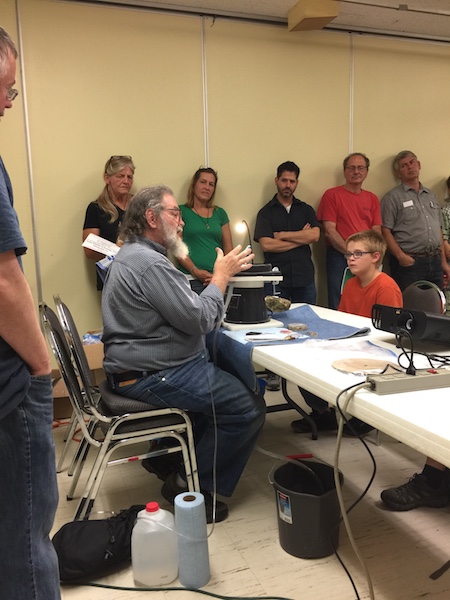

Mike Herrick presented a wonderful demonstration using his flat lap.

This machine uses diamond fused plates with various grit sizes to grind and smooth flat mineral surfaces. The harder the stone, the faster the wear on the plate – for example an agate wore out one in 4 hours!

Minerals should be cleaned before grinding – some can be soaked in CLR - Calcium, Lime, Rust Remover.

Mike demonstrated the flat lap using a fairly soft mineral – Ulexite, which is a borate mineral from California. When polished, Ulexite shows a fiber-optic effect, and is nicknamed “TV Rock”.

To polish that mineral, a 60 grit plate is used at first. There is a water reservoir which drips a small amount of moisture onto the plate. The water acts as a coolant and keeps dust down.

A timer is set to one minute. The mineral is moved around using gentle hand pressure, guiding it across the surface of the plate. The mineral is checked and can be done again if scratches are noted.

A 100 grit plate at 45 seconds is then used. A magnifying glass can be used to determine smoothness.

Each mineral and desired level of polish uses different grit plates – rhodochrosite may need 1200 to 14,000 grit plates to get a highly polished surface, for example.

If bald spots begin appearing in the grit plates, they should be replaced.

Thanks, Mike for sharing your talent with us!